[ad_1]

SRAM has revealed a patent detailing elastomer-damped shock finish mounts, mentioned to cut back excessive frequency, low amplitude vibrations transferred from the path to the rider. The tip mounts may be utilized on both finish of a shock, or each ends concurrently, to damp the low-level path chatter {that a} typical shock is unable to.

Sound acquainted? Certainly, this invention appears to carry out the exact same perform carried out by the ButterCups you’ll discover inside RockShox Final degree Zeb, Lyrik and Pike suspension forks. Truly, the inventor named on this specific patent (US 20230271672 A1) is Timothy Lynch. He’s the RockShox engineer whose thought it was to implement these elastomeric pucks on the model’s suspension forks after he found first hand the destructive results of high-frequency, low amplitude vibrations while utilizing a chainsaw.

The expertise is in reality not new. Corratec applied one thing comparable with a RockShox shock again in 2014 and 2015. Certainly, they took the 10Hz damper to manufacturing on a 100mm journey XC bike and a 175mm journey enduro bike, in a bid to supply frictionless small bump absorption.

Regardless, this very just lately revealed patent from SRAM (filed Feb twenty fifth, 2022) signifies that SRAM could also be seeking to develop the expertise additional. Right here’s extra.

Vibration-Damping Shock Finish Mounts from SRAM

Earlier than we dive into the small print, it’s pertinent to debate why such expertise is required, and what profit it might need for us mountain bikers. In any case, aren’t fashionable shocks adequate already? Certain, the overwhelming majority of them do a unbelievable job of compressing and rebounding to soak up medium to massive bumps, permitting our tires to keep up secure, constant contact with the bottom. Fashionable dampers are configured to manage these compression and rebound occasions to ship a clean, managed journey really feel for the overwhelming majority of riders.

A Flaw of the Fashionable Shock

What they don’t seem to be so good at doing is absorbing the high-frequency, low amplitude vibrations that come up from trucking over the a lot smaller, consecutive bumps that litter any path or gravel street. That’s as a result of, to ensure that any shock, air or coil, to compress or rebound, there’s a threshold pressure that have to be overcome. Seals across the air spring or piston have a certain quantity of stiction related to them. To get them sliding freely, the breakaway pressure have to be overcome.

These high-frequency, low amplitude vibrations don’t provide up sufficient pressure to beat this threshold, and they also aren’t absorbed by the shock. As an alternative, they’re transferred by means of the body and into the riders arms (or toes). That causes fatigue. We’re all fairly conversant in arm pump, proper?

What’s extra, these vibrations have been proven to illicit a big response from a rider’s immune system. This was proven by Dr Lewis Kirkwood, an Edinburgh Napier College scholar who devoted his PhD to the subject. Clearly, any expertise that may stop these vibrations from reaching the rider, must be. As long as it doesn’t impinge of the general driving expertise, that’s.

A Attainable Resolution

Evidentially, SRAM has appreciation of this, having applied the vibration-damping ButterCups on high-end RockShox suspension forks. The above reveals how two elastomeric pucks are compressed and expanded, both facet of a steel plate, to soak up vibrations which might be despatched up by means of the entrance wheel into the fork’s decrease legs. RockShox say their ButterCups add about 4mm of vertical compliance to your suspension and a median of 20% discount in path chatter from reaching your arms.

Now, it appears they’re contemplating implementing the expertise on rear shocks in a bid to cut back path chatter reaching your toes (and subsequently, quads).

How do the SRAM Shock Finish-Mounts Damp Vibrations?

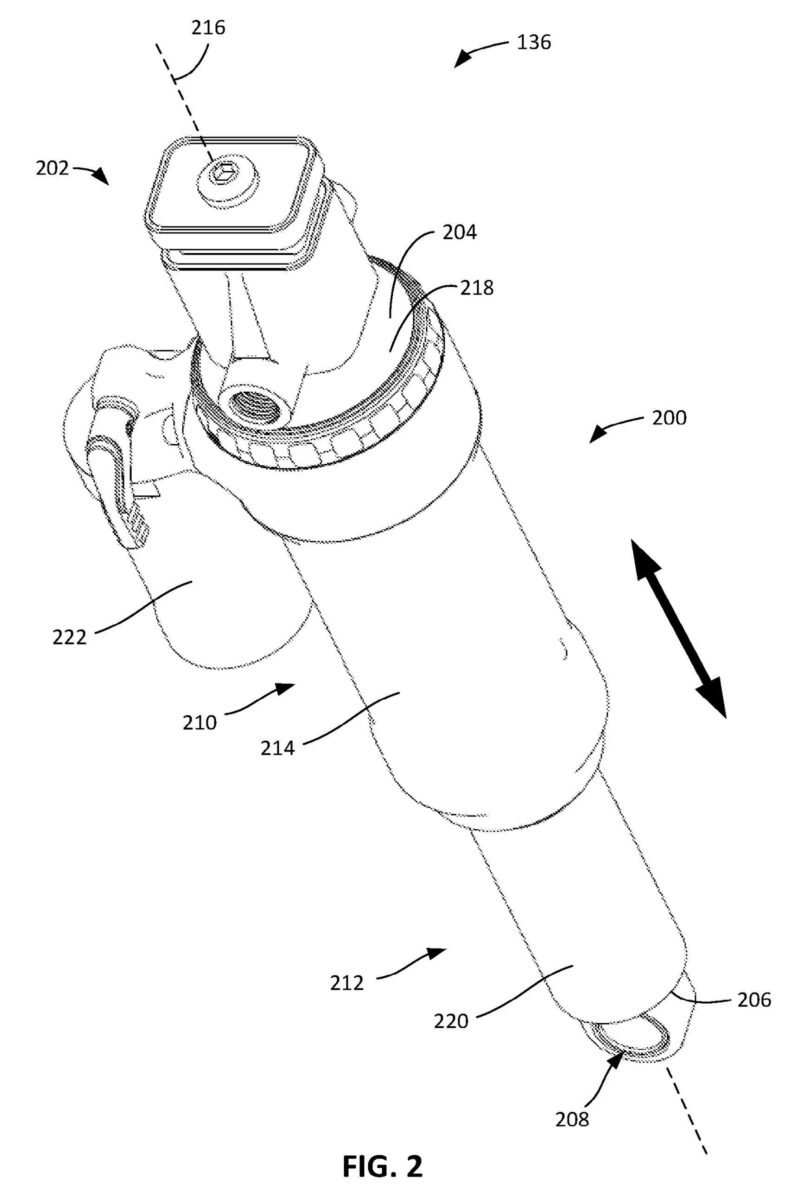

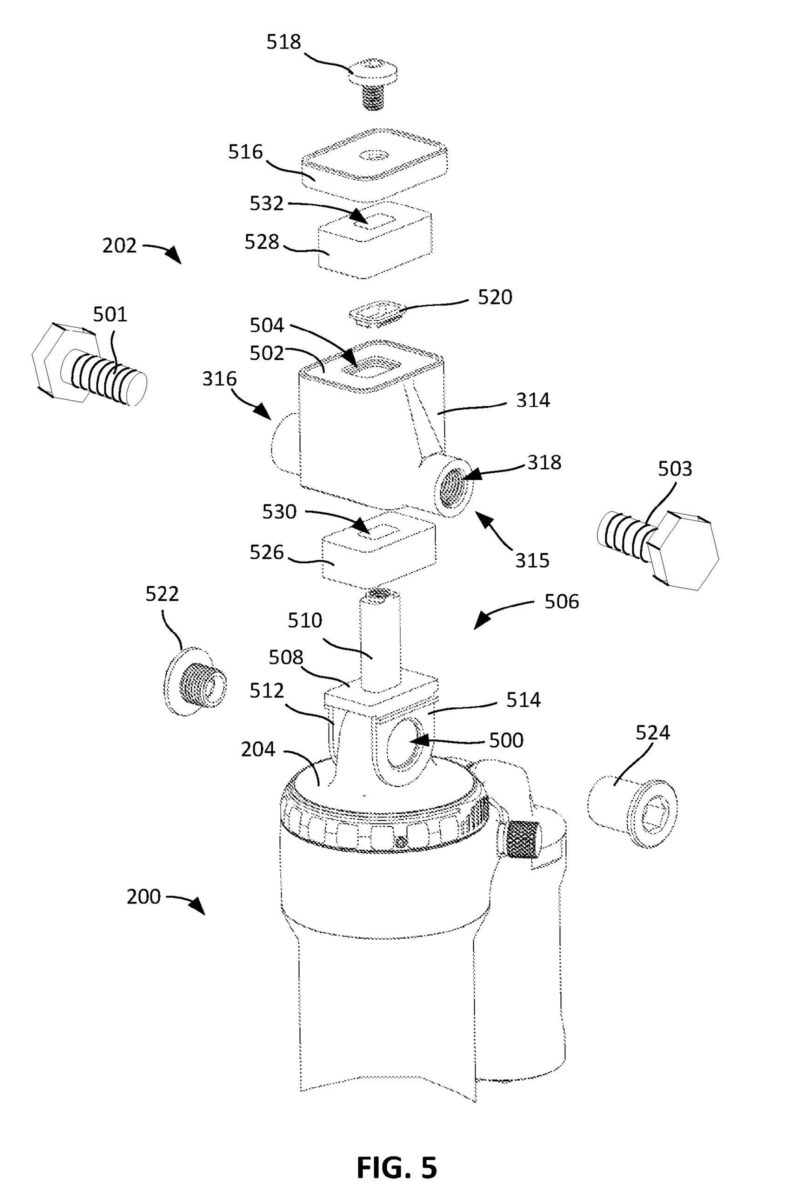

Primarily, the shock finish mounts described by SRAM are an middleman between the body (or rocker) and the shock. The shock finish mount bolts on to the shock through its eyelet or trunnion mount, and it bolts on to the body or rocker. However, these are two distinct mounts.

The shock finish mounts make use of this decoupling of the shock from its body or rocker mounting location, permitting relative motion between the 2. Stuffed into the area the place this relative motion happens are two elastomers that, by means of their compression and growth, are in a position to soak up vibrations – simply as proven for the ButterCups, above. The shock finish mount thereby turns into a spring itself, working in collection with the principle spring of the rear shock.

What’s key right here is that the pressure required to compress the elastomers is nicely under the breakaway pressure – the pressure required to push the shock into compression (or rebound). That is how SRAM suggest to cut back the amount of undesirable excessive frequency, low amplitude vibrations that attain the rider.

The patent reads, “…lengthy and gradual inputs are partially absorbed by the shock finish mount and transmitted to the shock absorber, whereas quick and brief inputs are absorbed simply within the shock finish mount. Consequently, the shock finish mount reduces vibrations felt by the rider (e.g., on the handlebars and/or the seat”.

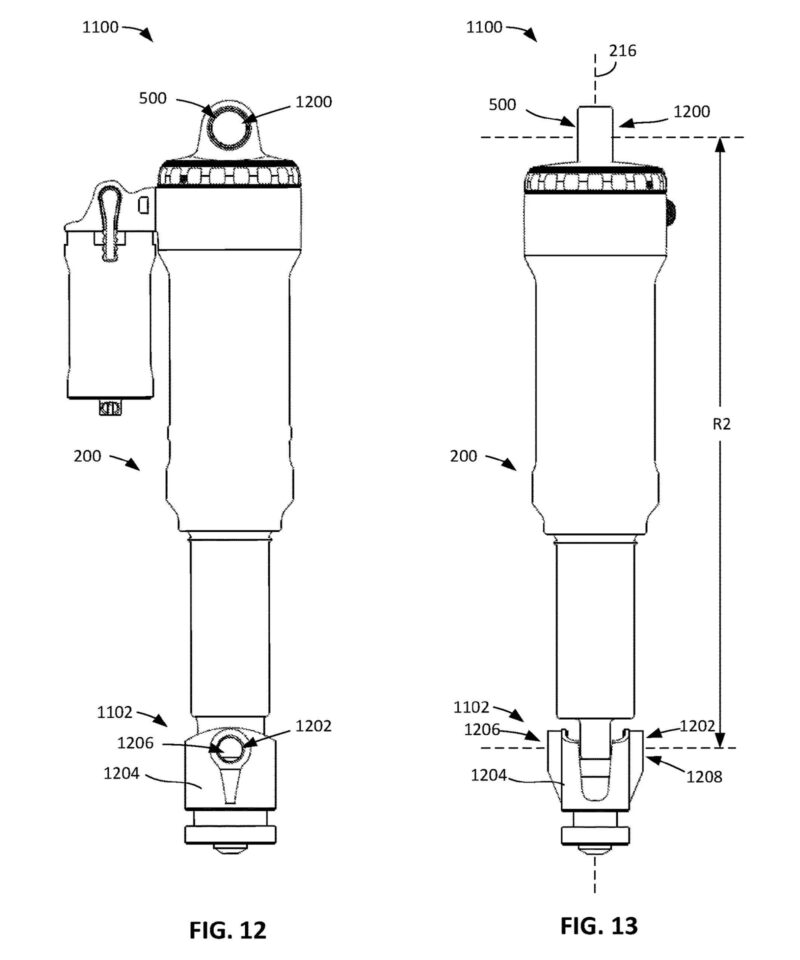

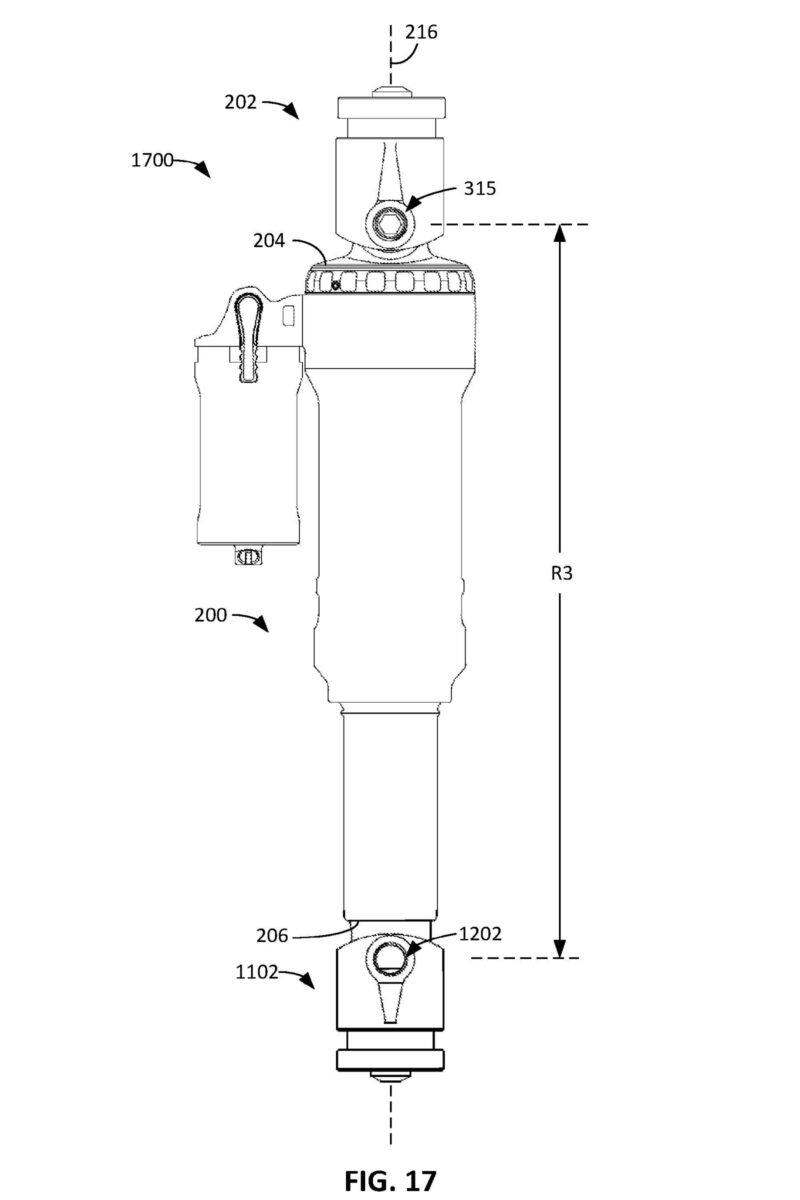

The doc reveals a shock operating a single shock finish mount (Fig. 12 & 13), and one other shock operating two of them – one on every finish (Fig. 17). For the latter instance, one can think about how the shock will basically oscillate over a really brief distance – simply a few millimeters, maybe – as a rider rolls alongside a gravel street, for instance.

This oscillation is described as a “fluttering” by the named inventor, Timothy Lynch.

How will the SRAM Shock Finish Mounts have an effect on body design?

Certain, the shock finish mounts described within the SRAM patent do take up appreciable area. How a lot area is but to be seen, however the patent says they are often smaller than 20mm, 30mm, or 40mm in size. It’s seemingly the dimensions shall be closely depending on the applying, be it on a downhill, enduro, path, XC and even gravel bike.

Importantly, the association of the shock finish mounts is such that the general size of the shock ought to stay unaffected. The elastomeric damping stack sits outwith the shock physique itself, so the eye-to-eye size doesn’t essentially must be shorter. Certain, some linkage designs shall be far more amenable to make use of of the shock finish mounts than others.

If the shock dimensions are totally unaffected by the addition of the shock finish mounts, then the bike’s leverage curve and suspension kinematic must be largely unaffected, too. If applied as SRAM foresee, these particular mounts stand to enhance the small bump sensitivity of any suspension platform.

All through the patent, solely air shocks are proven with the shock finish mounts put in. Nonetheless, SRAM do counsel they might be used on coil shocks, too. Nonetheless, air shocks exhibit way more stiction than coil shocks because of the presence of extra seals. For that cause, it appears it’s the air shock that stands to learn most from this invention.

Will the SRAM Shock Finish Mounts go to Manufacturing?

It’s inconceivable to know, after all. Manufacturers don’t at all times execute on the innovations they patent. Nonetheless, we’d guess that some type of this expertise will find yourself on future iterations of the RockShox Deluxe, Tremendous Deluxe, or Vivid shocks. Maybe even the SIDLuxe shocks, weight allowing. Given the existence of ButterCup expertise inside high-end RockShox forks, it appears this avenue of marginal positive aspects is an avenue that SRAM/RockShox are pleased to mince down.

We’ve reached out to SRAM for remark, and can replace this text with any additional info gleaned.

[ad_2]