[ad_1]

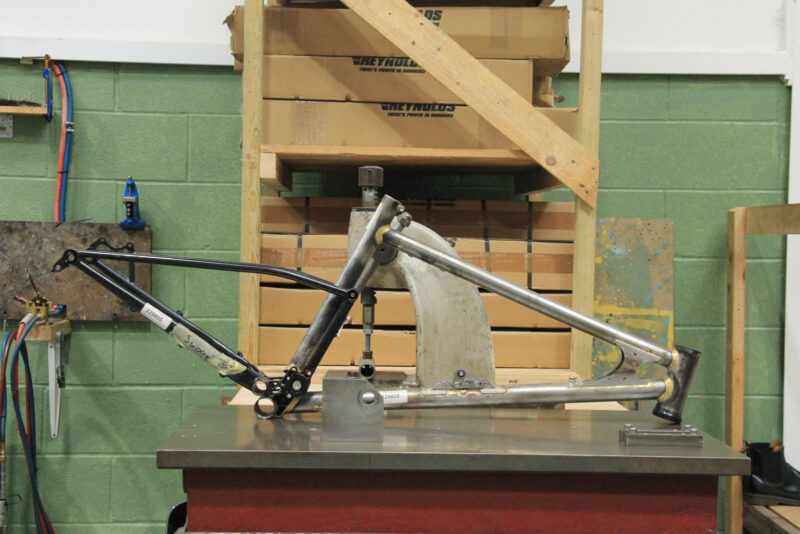

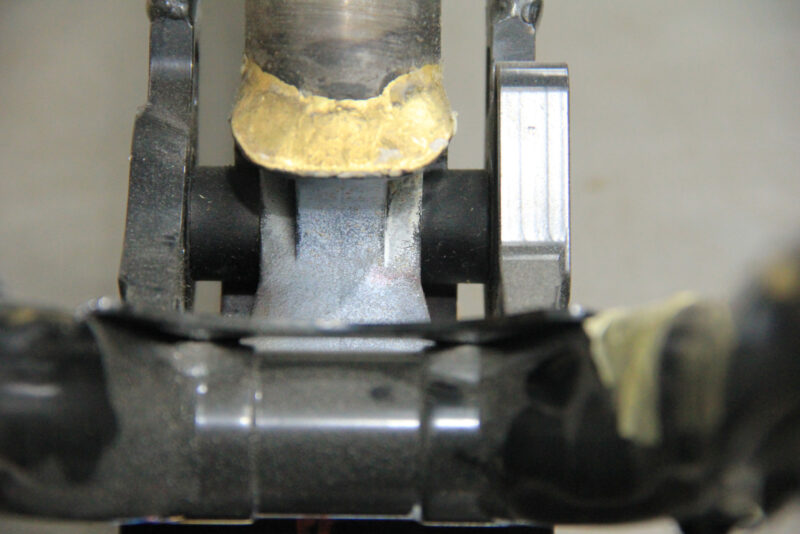

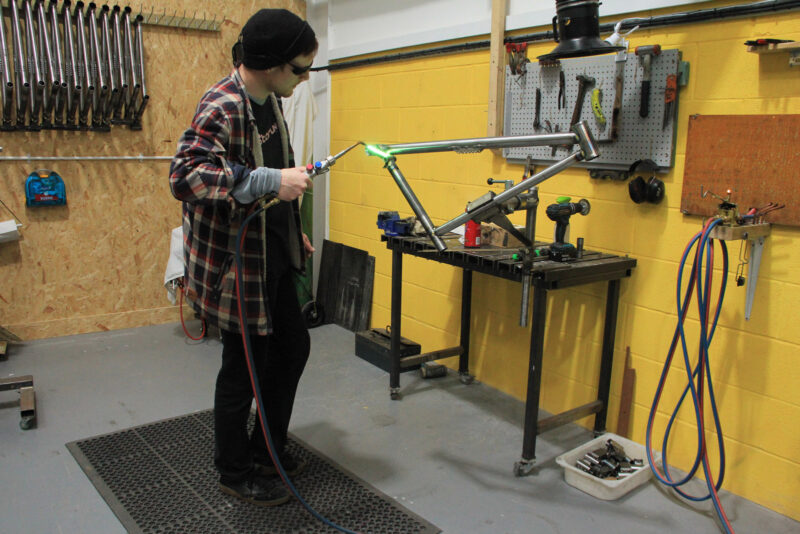

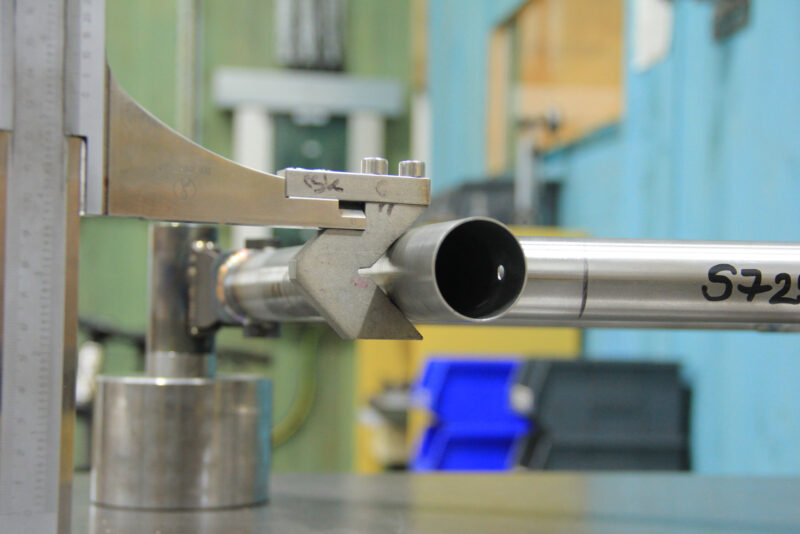

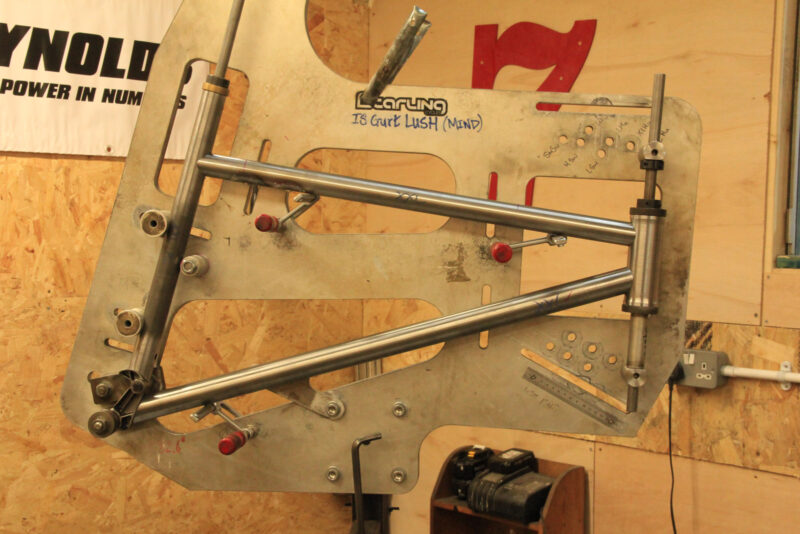

Starling Cycles is a UK producer of metal mountain bikes, most well-known for his or her aesthetically-pleasing executions of the standard single-pivot suspension platform. The model has come a good means since its fledgling backyard shed setup in 2015. For the time being, Joe has seven present manufacturing frames to his identify. The entrance triangles of most of those frames are fabricated in-house, at their Bristol workshop. In the meantime, nearly all of the swingarms are manufactured in Taiwan.

The Swoop 27.5″, the Twist Combined-Wheel, the Murmur 29″, and the latest MegaMurmur path and enduro bikes kind Starling’s “core” lineup. However, in addition they manufacture some fairly extra “uncommon” fashions. These embrace the wildly enjoyable Roost Hardtail, the Beady Little Eye (a 90mm journey mixed-wheel single-speed), and the Murmur Stainless. Additionally they supply a customized body constructing service for anybody after one thing particular.

However, Joe is one thing of a tinkerer, and is seemingly at all times working away on particular tasks. A few of them he labels “workouts in R&D”. Others are in order that area of interest {that a} restricted manufacturing run is the one viable possibility. Excellent examples of the latter embrace the Spur – a high-pivot 170mm journey gearbox-equipped enduro bike – and the Sturn – a single-speed high-pivot downhill bike with a Jack Shaft drivetrain association.

Earlier this 12 months, we stopped by the Starling Cycles HQ in Bristol, to seek out out what founder Joe McEwan has brewing for the corporate’s future.

All pictures from Bikerumor, until in any other case acknowledged

Interview | Joe McEwan on What’s to Come for Starling Cycles

Bikerumor: This 12 months, you launched the V3 Murmur, Twist and Swoop frames. Throughout their improvement, did you ever contemplate shifting away from the single-pivot suspension platform and in that case, for what causes?

Starling Cycles: I really like single pivot! With trendy coil shocks it rides nearly as good as multi-links, if not higher in lots of instances! I wish to have a vertical shock sitting near the seat tube: for aesthetics, commonality in manufacture between sizes and extra body area. However I can’t see methods to obtain this elegantly with out a linkage, so it’s a compromise too far!

Bikerumor: You’ve dabbled in using gearboxes, particularly with an Effigear unit on the Spur – a motorbike you say is the very best descender you’ve ever made. Do you assume the gearbox mountain bike will ever make it into the mainstream, and do intend to carry a gearbox-dedicated body to manufacturing?

Starling Cycles: The Spur gearbox bike we made was superb. The suspension efficiency and silence made it probably the most superb descending bike I’ve ever ridden. However, there’s a little little bit of drag which implies it’s best suited to a extra gravity oriented bike. I don’t assume meshing gears at low revs will ever be as environment friendly as a sequence, somebody extra educated on drivetrain techniques can agree or disagree, little question.

We had some manufacturing challenge with Effigear, principally as a consequence of Covid provide chains, but it surely appears they’re on prime of it now, so we could also be providing the Spur once more someday quickly!

When it comes to the gearbox, in home we now have a design and are manufacturing a prototype 2 pace field, primarily meant to trial the know-how. Subsequent variations could have 4 gears.

Bikerumor: In your workshop, there’s a metal eBike hanging from the demo bike rail. Will we be see a Starling Cycles eMTB within the not-too-distant future? In that case, are you able to give us any information on the way it will materialize?

Starling Cycles: The metal ebike by no means actually labored out. It’s fairly tough to accomodate the advanced shapes wanted for motors and batteries and suspension in metal. However, I feel as motor and battery know-how permits for extra compact techniques, I would be capable of do a Starling ebike and nonetheless hold the elegant design I worth a lot!

However, there may be additionally the counter level that Starlings undoubtedly don’t appear to be ebikes. Whereas, with many fats tubed carbon bikes it’s tough to inform. So, if you’re on the prime of a hill on a Starling, everybody is aware of you pedaled it as much as the highest!

However, I’m additionally engaged on a parallel mission underneath a brand new model to develop a reasonably particular ebike, so hold your eyes open for that one….

Bikerumor: Final 12 months, you teased a carbon eMTB with braided, thermoplastic tubes, developed in collaboration with the Nationwide Composites Middle. Are you able to give us an replace on that mission?

Starling Cycles: This mission is shifting forward, however slowly. That’s all I can say!

Bikerumor: Mountain Bike geometry has come a good distance within the final 5 years; do you assume now we have reached the top of the lengthy, low and slack geometry pattern, or do you are feeling there may be extra to be gained from pushing this additional?

Starling Cycles: Mountain bike geometry has modified, and now we have a greater understanding of what’s required for various kinds of driving. The lengthy, low, slack fits tough excessive pace terrain, however possibly on the expense of some pop and maneuverability. Personally, the extra I give it some thought, the extra I feel we’d like to consider how we journey and what geometry fits our wants, fairly than simply considering making it so long as potential is greatest. There’s an ergonomic facet too.

So to attempt to condense my considering: Longer stays add maneuverability, shorter stays add pop and maneuverability. It’s essential decide the compromise to fit your driving model.

Taller riders want larger bikes, larger bikes want longer stays to steadiness out the bike. And, the reverse for shorter riders. Longer journey bikes add grip and bump consuming on the expense of pedalling and pop. Shorter journey bikes present a firmer platform for higher pedalling and pop, on the expense of grip and bump consuming. It’s essential decide the compromise to fit your driving model.

Wheels/tyres have an enormous impression on how bikes journey. Heavy wheels and difficult tyres for grip and management, the burden really retains them secure within the tough, however they’re more durable to pedal. Mild wheels and quick rolling tyres for pedalling pace on clean terrain and quick climbing, however they’re horrible in tough terrain. It’s essential decide the compromise to fit your driving model.

My fundamental thought is that nothing is the golden ticket, you at all times want to select the place you need your compromise to take a seat. Though, advertising and marketing tries to inform you in any other case, it’s simply not true! I attempt to present a spread of bikes that permits you to decide the compromise you need with minimal trouble!

Bikerumor: Do you may have any predictions for the place mountain bike know-how is headed within the subsequent 10 years, and the way will Starling Cycles be part of that?

Starling Cycles: I’ve a little bit of a battle on this. I’m an engineer and I really like know-how and bettering efficiency. However, we’re biking for enjoyable, even with racing we’re principally doing it for enjoyable, and we had as a lot enjoyable on bikes from 20 years in the past as we do now.

I feel the incremental positive factors we see now are pushed extra by advertising and marketing and the necessity for change than any precise better enjoyment for the game. I suppose the very fact they don’t break as a lot anymore is a constructive. However apart from that, we’d have as a lot enjoyable on a Klunker. I feel the emergence of gravel is partly pushed by this.

So, I feel the pattern for the longer term is much less know-how and extra participating driving on inventory Klunkers with ‘requirements’ which are actual requirements!

Bikerumor: What are the main challenges confronted by the small to medium measurement bicycle producers in Britain in the present day?

Starling Cycles: Being a British Producer will not be straightforward. With out getting too political, manufacturing is simply not valued within the UK. The individuals getting cash, with minimal danger, are property brokers (don’t get me began), attorneys, solicitors, finance, advertising and marketing individuals. They add nothing, however take all the things. Whereas within the EU and plenty of different locations it’s understood that manufacturing is essential to a robust economic system and it’s revered. Engineers are revered, not simply seen as bizarre geeks.

British manufacturing can be devalued, notably with bikes, by firms claiming their merchandise are UK manufactured, however the truth is they’re solely assembled right here from components made elsewhere. We get our swingarms made in Taiwan, however are very clear about it, different firms are a lot much less clear…

We must be pleased with what we are able to do right here and shout about it. There’s numerous nice UK manufacturers doing thrilling issues with manufacturing within the UK; Starling, Atherton Bikes, Stanton, Moulton, Brompton and plenty of extra. The remainder of the world take pleasure in supporting their native manufacturers. UK manufacturing was killed within the 80s with crap vehicles, so no one buys British anymore! So, we’ll wrestle on. Sorry, that did get a bit political.

If you happen to had been to order a body in the present day, you’d wait someplace between 8-16 weeks for supply. Starling are working exhausting to extend their UK manufacturing capability by coaching a 3rd body builder to affix the staff, hoping to carry lead time right down to round 4 weeks.

[ad_2]